-

Your SAP ERP

Get what you want. Choose your SAP ERP.

- Products

-

Rapid Apps

Executive AppsUser AppsIT Apps

-

Services

-

Support

Liquid UI CommunityLIQUID UI TOOLS

- Resources

- Company

- Free Trial

- Background

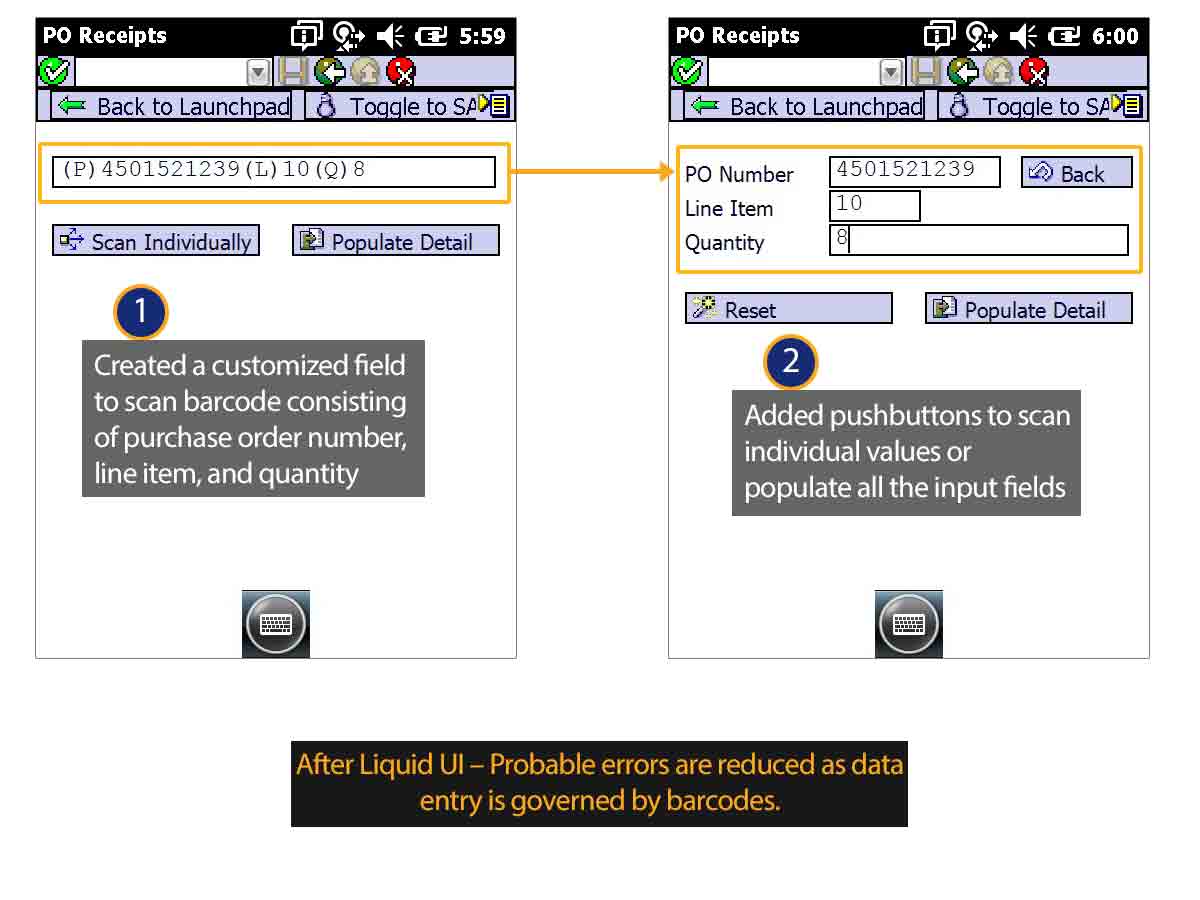

- Challenge

- Solution

- Results

Products

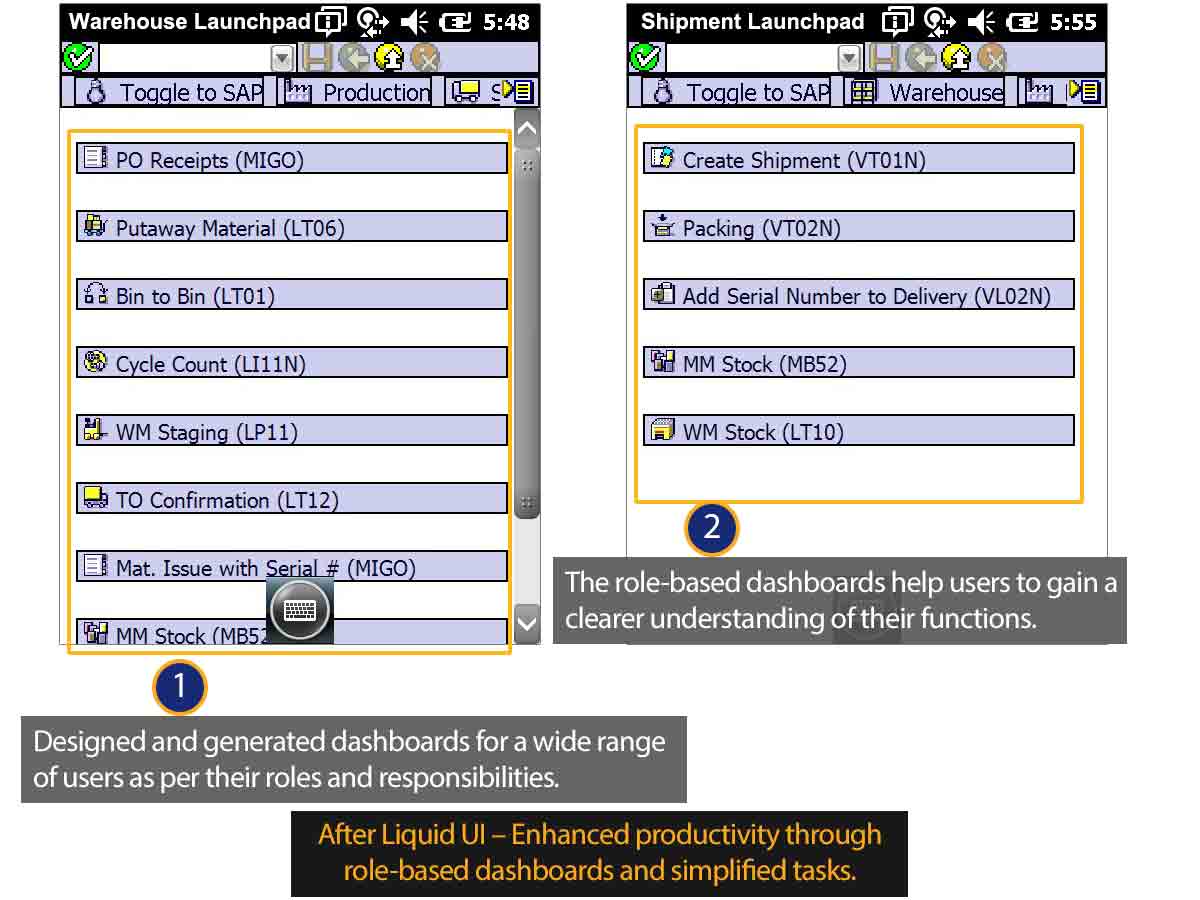

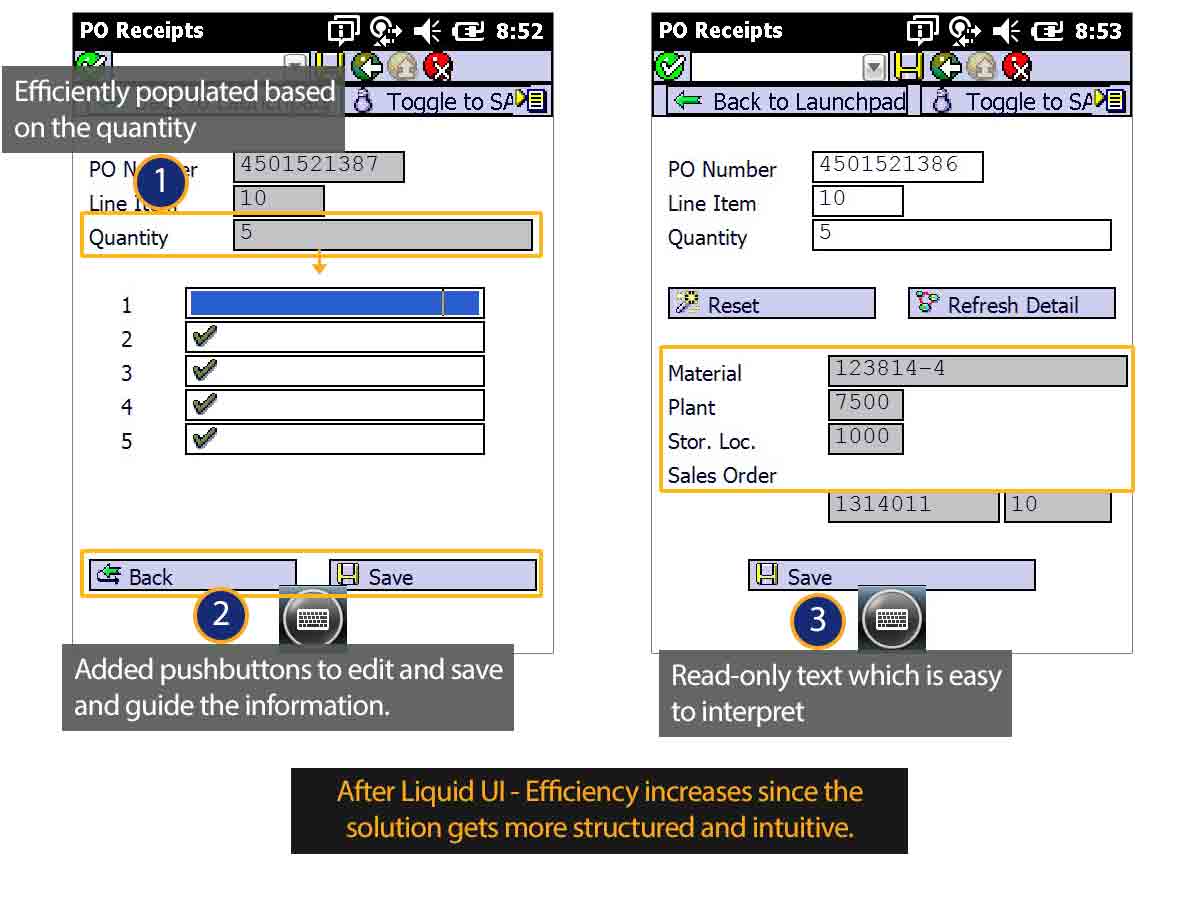

- Liquid UI for Scanguns

SAP Process

- Warehousing

See All Stories